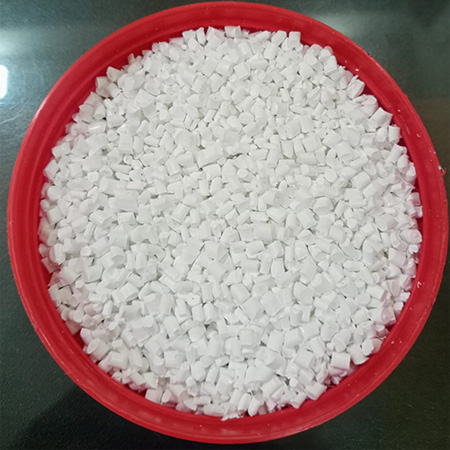

White Masterbatch

White masterbatch is a concentrated mixture of titanium dioxide (TiO2) or other white pigments dispersed in a carrier resin, along with additives like dispersants and processing aids. It serves the primary purpose of imparting white color to plastic products during the manufacturing process. Here’s how white masterbatch is used and its applications with below text:

( NOTE :-Quantity are in Kg & Rates will be changed as per Raw Material Cost, Transport Cost & Packaging Cost )

Description

Usage and Application:

Coloring Plastics: White masterbatch is added to natural (unpigmented) polymer resins during the processing of plastics to achieve a consistent and uniform white color throughout the product.

Opacity and Coverage: Titanium dioxide, the most common pigment used in white masterbatch, provides excellent opacity and coverage, ensuring that the underlying color of the plastic is completely masked.

UV Stabilization: Some white masterbatches may include UV stabilizers to protect the plastic from degradation caused by exposure to sunlight.

Enhanced Properties: It can improve the mechanical properties, such as stiffness and impact resistance, of the final plastic product.

Applications:

Packaging: White masterbatch is extensively used in the packaging industry for products like food containers, bottles, films, and various types of packaging materials.

Automotive: It is used in automotive parts such as interior trims, dashboards, and exterior components.

Construction: White masterbatch finds applications in construction materials such as pipes, profiles, window frames, and flooring.

Consumer Goods: It is used in consumer goods such as toys, household appliances, furniture, and electronic devices.

Benefits:

Color Consistency: Ensures consistent color quality and appearance of the final plastic product batch after batch.

Cost-Effectiveness: Allows manufacturers to use natural resin in bulk and add white colorant during processing, which is often more cost-effective than purchasing pre-colored resin.

Customization: Manufacturers can choose from different grades and concentrations of white masterbatch to achieve specific shades and properties required for their products.

Functional Properties: Besides coloration, white masterbatch can enhance the physical and chemical properties of plastics, making them suitable for a wide range of applications.

Overall, white masterbatch plays a crucial role in the plastics industry by providing a reliable method for achieving white coloration in plastic products while offering additional benefits such as UV protection and improved mechanical properties.

#Masterbatch#PolymerAdditives#ColorMasterbatch#PlasticProcessing#PolymerIndustry#MasterbatchManufacturer#PolymerCompounding

#AdditiveManufacturing#PlasticMasterbatch#PolymerTechnology