Low Smoke Zero Haloge

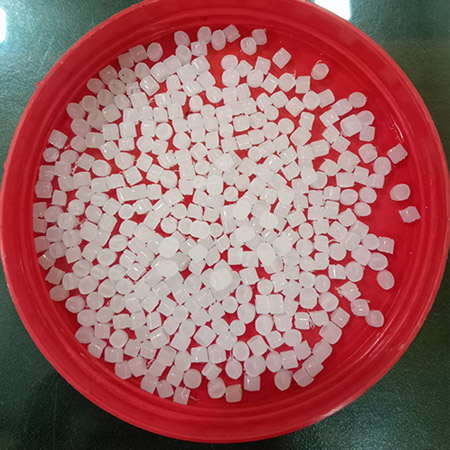

LSZH (Low Smoke Zero Halogen) compound is a type of thermoplastic material used primarily in the manufacture of cables and wires where safety and environmental concerns are paramount.Developed to meet the rigorous demands of modern applications, our halogen-free solutions excel in mechanical strength, flame resistance, and processability, setting new standards in the industry. We specialize in high-filled materials that achieve exceptional flame retardancy without compromising on environmental stress cracking resistance—a critical factor for long-term durability in challenging environments.

( NOTE :-Quantity are in Kg & Rates will be changed as per Raw Material Cost, Transport Cost & Packaging Cost )

Description

Our materials undergo extensive testing under severe conditions of moisture, temperature fluctuations, and mechanical stress, ensuring reliability for low and medium voltage applications. They are engineered to comply with the latest CPR (Construction Products Regulation) standards, making them ideal for insulation and sheathing in diverse environments.

We offer comprehensive solutions for both Copper LAN and Optical Fiber applications, tailored to meet specific customer requirements and industry standards. Our commitment to innovation ensures that our materials not only meet but exceed expectations for high processability, flame resistance, and chemical durability.

Designed with compatibility in mind, our materials are optimized for use with existing equipment while meeting stringent performance specifications. Whether in telecommunications, infrastructure, automotive, or aerospace sectors, our halogen-free solutions provide peace of mind with their robust performance and adherence to safety and environmental standards.

Customized solution:- We specialize in offering customized solutions tailored precisely to your specifications. Our one-pack systems combine specialty additives to provide a versatile solution with multiple properties in a single masterbatch. This approach minimizes complexity, reduces the risk of error from using multiple additives, and optimizes efficiency in production.

#Masterbatch#PolymerAdditives#ColorMasterbatch#PlasticProcessing#PolymerIndustry#MasterbatchManufacturer#PolymerCompounding

#AdditiveManufacturing#PlasticMasterbatch#PolymerTechnology