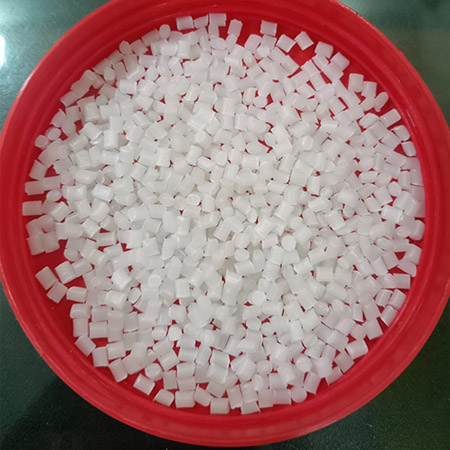

Additive Masterbatch

Additive masterbatch is a specialized type of masterbatch used in the plastics industry to introduce various additives into plastic products during the manufacturing process. These additives can impart specific properties or functionalities to the plastic, beyond coloration. Here’s an overview of the types of additives commonly used in additive masterbatch and their applications:

( NOTE :-Quantity are in Kg & Rates will be changed as per Raw Material Cost, Transport Cost & Packaging Cost )

Description

UV Stabilizers: These additives protect plastics from UV radiation, which can cause degradation and discoloration over time. UV stabilizers are crucial for outdoor applications where prolonged exposure to sunlight is expected, such as in construction materials, automotive parts, and outdoor furniture.

Antioxidants: Antioxidants help prevent degradation of plastics due to oxidation, which can occur from exposure to heat, oxygen, or light. They are used to enhance the longevity and performance of plastic products, particularly in high-temperature applications or where exposure to harsh environmental conditions is likely.

Antimicrobial Agents: Additive masterbatches containing antimicrobial agents are used in plastics intended for healthcare settings, food packaging, and other applications where preventing microbial growth and maintaining hygiene are critical.

Flame Retardants: Flame retardant additives reduce the flammability of plastics, making them suitable for applications where fire safety is paramount, such as in electronics, automotive interiors, and building materials.

Antistatic Agents: These additives reduce static electricity buildup on the surface of plastic products, which is beneficial in applications like electronic devices, packaging for sensitive electronic components, and textiles.

Slip Agents: Slip additives improve the surface properties of plastics by reducing friction, making them easier to handle and process. They are used in packaging films, where smooth surface characteristics are desirable.

Processing Aids: Additive masterbatches can include processing aids that improve the flow of the molten plastic during processing, reduce processing temperatures, or enhance mold release properties.

Applications:

Packaging: Additive masterbatch is extensively used in packaging applications such as food packaging, medical packaging, and industrial packaging to enhance properties like UV resistance, barrier properties, and hygiene.

Automotive: In the automotive industry, additive masterbatch is used for components requiring UV resistance, flame retardancy, and enhanced mechanical properties.

Construction: Building and construction materials benefit from additive masterbatch additives such as UV stabilizers, flame retardants, and antioxidants to improve durability and performance in outdoor and structural applications.

Electronics: Plastics used in electronics often incorporate additive masterbatch with antistatic agents and flame retardants to meet safety and performance standards.

Healthcare: Additive masterbatch with antimicrobial agents is used in medical devices, equipment, and packaging to maintain sterile conditions and prevent microbial growth.

Benefits:

Enhanced Properties: Additive masterbatch allows manufacturers to tailor the properties of plastic products to meet specific performance requirements, such as UV resistance, flame retardancy, and antimicrobial protection.

Cost-Effectiveness: Incorporating additives via masterbatch is often more economical than adding them separately during processing, as it ensures uniform distribution and reduces processing time and costs.

Regulatory Compliance: Helps manufacturers meet regulatory standards and certifications for safety, hygiene, and environmental protection in various industries.

Additive masterbatch plays a crucial role in enhancing the functionality, performance, and longevity of plastic products across a wide range of industries, offering tailored solutions to meet specific application requirements and regulatory standards.

#Masterbatch#PolymerAdditives#ColorMasterbatch#PlasticProcessing#PolymerIndustry#MasterbatchManufacturer#PolymerCompounding

#AdditiveManufacturing#PlasticMasterbatch#PolymerTechnology